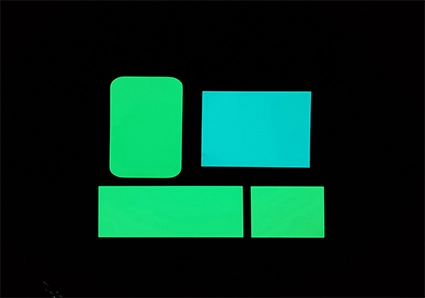

The unique luminescent properties of photoluminescent pigments allow them to provide additional visual effects and practicality in various application scenarios, such as enhancing night visibility or adding decorative effects. With technological advances and changing market demands, photoluminescent pigments are increasingly favored by designers and consumers for their durability, variety of colors, and environmental friendliness.

Definition of Photoluminescent Pigment

Photoluminescent pigments, often referred to as photoluminescent pigments or long-lasting luminescent pigments, are the main substances that make coatings glow. Photoluminescent pigments are powdered photo-storage luminescent materials, typically composed of the sulfides of zinc, calcium, barium, or strontium, a small amount of flux (such as sodium chloride), and trace amounts of activators. The luminescent color of the pigment can vary depending on the type of activator used.

Classification of Photoluminescent Pigment

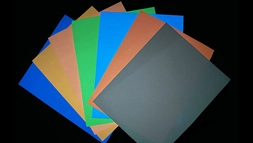

There are two main categories of photoluminescent pigments provided by phosphorescent powder supplier: inorganic luminescent pigments and organic luminescent pigments. Inorganic luminescent pigments are mainly divided into three categories: zinc sulfide-based luminescent pigments, rare earth-activated alkaline earth metal aluminates, and rare earth-doped silicates.

Organic luminescent pigments are diverse, highly tunable, rich in color, and have high color purity, but they generally have poor weather resistance and chemical resistance, which greatly limits their application fields. In contrast, inorganic luminescent pigments have good weather resistance, chemical resistance, high luminescence intensity, and long afterglow time, making them the preferred choice for energy-storing photoluminescent pigments.

Challenges of Photoluminescent Pigment

Despite their numerous excellent properties, energy-storing luminescent pigments still have limited applications, especially in larger areas such as interior and exterior wall coatings and flooring, mainly due to the following reasons:

Economically, energy-storing photoluminescent pigments are costly, making large-scale applications difficult;

Technically, the comprehensive performance of energy-storing photoluminescent pigments cannot meet the requirements of varied environments. Specifically, they have weak weather resistance, impact resistance, and scratch resistance. The pigments are large in size, have poor compatibility with resins, and do not disperse well in coatings. The complex coating preparation and application processes often require the use of primers or topcoats. Additionally, coatings contain a substantial amount of organic solvents, leading to significant environmental pollution during application.

From a theoretical research perspective, much of the focus in the field is on luminescence intensity, afterglow time, and durability of photoluminescent pigments, with a notable lack of systematic basic theoretical research.

English

English